Home> Company News> 608ZZ Bearing Interchange Guide: Ensuring Seamless Replacement

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

Introduction

Welcome to the 608ZZ Bearing Interchange Guide: Ensuring Seamless Replacement. This guide delves into the intricate world of 608ZZ bearings, exploring their ubiquitous presence and critical role in various applications. Understanding the significance of interchangeability is paramount in the realm of bearings, where precise fitment can make a substantial difference in operational efficiency and longevity.

Overview of 608ZZ Bearings and Their Widespread Use

608ZZ bearings, a variant of the 608 series bearings, are miniature radial ball bearings commonly used in machinery across industries such as manufacturing, automotive, and robotics. These bearings feature a 8mm inner diameter, 22mm outer diameter, and 7mm width, making them versatile for both light to moderate radial and axial loads.

Importance of Interchangeability in Bearing Applications

The ability to interchange bearings seamlessly is crucial for maintenance, repair, and operations (MRO) teams. It ensures downtime is minimized during replacement tasks and facilitates inventory management. Engineers rely on interchangeability to quickly swap out worn bearings without requiring modifications to existing equipment, thereby reducing costs and improving overall operational efficiency.

Facilitates seamless replacement

The main purpose is to provide a comprehensive insight into the 608ZZ bearing, focusing on its interchangeability aspects. By understanding how 608ZZ bearings can be effectively substituted across different applications and brands, readers will gain valuable knowledge to enhance their maintenance strategies and optimize equipment performance.

Understanding 608ZZ Bearings

we delve into the essential aspects of 608ZZ bearings, exploring their definition, specifications, key features, variations in design, and widespread applications.

Definition and Specifications of 608ZZ Bearings

608ZZ bearings are miniature radial ball bearings characterized by their 8mm inner diameter, 22mm outer diameter, and 7mm width. The 'ZZ' designation signifies shielded bearings, which are equipped with metal shields on both sides to protect against contaminants and retain lubrication. These bearings are crafted from high-quality steel or ceramic materials, ensuring durability and reliable performance under various operating conditions.

Key Features and Variations in 608ZZ Designs

Key features of 608ZZ bearings include their smooth operation, low friction coefficient, and ability to sustain moderate radial and axial loads. They are available in various material options such as chrome steel, stainless steel, and hybrid ceramic, catering to specific application requirements for corrosion resistance, high-speed operation, or enhanced durability.

Variations in design encompass different shield configurations (e.g., single shielded, double shielded), cage materials (e.g., steel, nylon), and lubrication options (e.g., grease, oil). These variations allow engineers to select the most suitable 608ZZ bearing based on factors like environmental conditions, speed capabilities, and load demands.

Common Industries and Applications Using 608ZZ Bearings

608ZZ bearings find extensive use across a diverse range of industries and applications:

|

Industry/Application |

Applications |

|

Manufacturing |

Conveyor systems, assembly lines, packaging machinery |

|

Automotive |

Electric motors, alternators, air conditioning compressors |

|

Robotics |

Robotic arms, joints, precision motion control systems |

|

Skateboarding |

Skateboard wheels for smooth rolling capabilities |

|

Household Appliances |

Fans, vacuum cleaners, kitchen appliances |

Their versatility and robust design make 608ZZ bearings indispensable in maintaining operational efficiency and reliability across various mechanical systems.

Interchangeability Factors

We explore the critical factors influencing the interchangeability of 608ZZ bearings, including size, load capacity, compatibility standards, and the benefits of using interchangeable bearings in maintenance and operations.

Parameters Affecting Interchangeability

Size: The dimensions of 608ZZ bearings, specifically the inner diameter, outer diameter, and width, play a crucial role in their interchangeability. Manufacturers adhere to standardized dimensions to ensure compatibility across various applications and equipment.

Load Capacity: Understanding the maximum radial and axial loads that 608ZZ bearings can withstand is essential for determining their interchangeability. Bearings with higher load capacities may be required for applications with heavier loads to ensure optimal performance and longevity.

Compatibility Standards and Certifications

ISO Standards: 608ZZ bearings adhere to international standards set by the International Organization for Standardization (ISO), such as ISO 492 for radial bearings and ISO 76 for dimensions and tolerances of ball and roller bearings. Compliance with these standards ensures that bearings from different manufacturers are interchangeable without compromising performance.

Benefits of Interchangeable Bearings in Maintenance and Operations

Reduced Downtime: Interchangeable bearings allow maintenance teams to replace worn-out bearings quickly and efficiently, minimizing equipment downtime during repairs.

Cost Savings: Standardized interchangeability simplifies inventory management and procurement processes, potentially reducing overall costs associated with spare parts.

Flexibility: Engineers have the flexibility to choose bearings from different manufacturers while maintaining performance standards, providing options for sourcing and pricing.

Incorporating interchangeable 608ZZ bearings into maintenance strategies enhances operational efficiency and reliability, making them indispensable components in various industrial and mechanical applications.

|

Brand |

Part Number |

Specifications |

Application |

|

SKF |

608-2Z |

8mm ID, 22mm OD, 7mm width, shielded |

Robotics, Manufacturing |

|

NSK |

608ZZ |

8mm ID, 22mm OD, 7mm width, shielded |

Automotive, Robotics |

|

NSK |

608ZZ |

8mm ID, 22mm OD, 7mm width, shielded |

Automotive, Robotics |

|

NTN |

608ZZ |

8mm ID, 22mm OD, 7mm width, shielded |

Robotics, Automotive |

|

Timken |

38PP |

8mm ID, 22mm OD, 7mm width, shielded |

Manufacturing, Aerospace |

Identifying Compatible Bearings

We delve into the methods and tools used to identify compatible 608ZZ bearings, crucial for ensuring seamless replacements and maintenance efficiency.

Methods to Determine 608ZZ Bearing Compatibility

Measurement and Dimension Verification: The first step in determining compatibility involves accurately measuring the inner diameter, outer diameter, and width of the existing 608ZZ bearing. This ensures that replacements match the exact dimensions required by the application.

Load Capacity Assessment: Evaluating the maximum radial and axial loads that the bearing will endure is essential. Manufacturers provide load capacity ratings for their bearings, aiding in selecting replacements that can handle similar operational demands.

Cross-Referencing Bearing Specifications and Part Numbers

Manufacturer Specifications: Cross-referencing manufacturer-provided specifications such as part numbers, series numbers, and material compositions helps identify suitable replacements. These specifications ensure that the new bearing meets or exceeds the performance characteristics of the original.

Catalogs and Databases: Utilizing bearing manufacturer catalogs, online databases, and industry resources simplifies the process of finding compatible replacements. These tools provide comprehensive information on bearing dimensions, load capacities, and application suitability.

Tools and Resources for Identifying Suitable Replacements

Online Bearing Interchange Guides: Websites and applications offer interactive tools that allow users to enter existing bearing details to find compatible alternatives from various manufacturers.

Engineering Support: Leveraging support from bearing suppliers and engineering teams can provide insights into technical specifications and recommend suitable replacements based on application requirements.

Identifying compatible 608ZZ bearings ensures that maintenance teams can swiftly replace worn-out components, minimizing downtime and optimizing equipment performance across various industrial sectors.

Practical Guide to Replacement

We provide a step-by-step guide for replacing 608ZZ bearings, essential tools and equipment needed for seamless installations, and precautions to ensure successful replacements.

Step-by-Step Process for Replacing 608ZZ Bearings

|

Step |

Details |

|

Preparation |

Identify Bearing Type: Determine specific 608ZZ variant based on dimensions and load requirements. |

|

|

Gather Tools: Ensure you have bearing pullers, wrenches, and cleaning materials ready. |

|

Removal of Old Bearing |

Secure Equipment: Power down machinery and secure it to prevent accidents. |

|

|

Use of Tools: Use appropriate tools to gently remove the old bearing without damaging surrounding components. |

|

Cleaning and Inspection |

Inspect Housing: Check for wear or damage in the bearing housing. |

|

|

Clean Surfaces: Thoroughly clean housing and shaft to remove debris and old lubricants. |

|

Installation of New Bearing |

Apply Lubrication: Apply recommended lubricant to the new 608ZZ bearing. |

|

|

Align and Insert: Align bearing with shaft and gently press or tap into place using suitable tool. |

|

Verification and Testing |

Rotate Freely: Ensure new bearing rotates smoothly without resistance. |

|

|

Check Alignment: Verify bearing alignment to avoid premature wear. |

Tools and Equipment Required for Seamless Installations

Bearing Puller: For safely removing old bearings without damaging surrounding components.

Wrenches: Ensure proper torque application during installation.

Cleaning Materials: To clean bearing housings and shafts effectively.

Lubricants: Suitable grease or oil for lubricating bearings before installation.

Precautions and Best Practices to Ensure Successful Replacements

Handle with Care: Avoid dropping or mishandling bearings to prevent damage.

Follow Manufacturer Guidelines: Adhere to recommended torque settings and lubrication practices.

Inspect Surrounding Components: Check for wear or damage that could affect bearing performance.

Following this practical guide ensures smooth and efficient replacements of 608ZZ bearings, minimizing downtime and maintaining equipment reliability across various industrial applications.

Case Studies and Examples

We explore real-world case studies of successful 608ZZ bearing replacements, the challenges encountered, solutions implemented, and lessons learned to optimize interchangeability.

Real-World Examples of Successful 608ZZ Bearing Replacements

Automotive Sector

Industry: Automotive manufacturing

Challenge: A production line faced frequent downtime due to worn-out 608ZZ bearings in robotic arms used for assembly.

Solution: Engineers implemented a proactive maintenance schedule and sourced high-quality, OEM-compatible 608ZZ bearings.

Outcome: Downtime reduced by 30%, improving production efficiency and lowering maintenance costs.

Industrial Machinery

Industry: Heavy machinery manufacturing

Challenge: Heavy-duty conveyor systems experienced bearing failures affecting throughput.

Solution: Upgraded to 608ZZ bearings with higher load capacities and improved sealing for enhanced durability.

Outcome: Increased system reliability, reducing maintenance frequency and operational disruptions.

Challenges Faced and Solutions Implemented

Compatibility Issues: Ensuring new bearings fit precisely within existing assemblies.

Solution: Conducted thorough measurements and consulted with bearing suppliers for exact replacements.

Environmental Conditions: Bearings exposed to harsh environments leading to premature wear.

Solution: Opted for 608ZZ bearings with corrosion-resistant coatings and improved sealing.

Lessons Learned for Optimizing Interchangeability

Standardization: Maintaining a standardized inventory of 608ZZ bearings across equipment reduces procurement complexity.

Engineering Expertise: Involving engineers early in the replacement process ensures technical compatibility and optimal performance.

Continuous Improvement: Regularly reviewing and updating maintenance practices based on bearing performance data enhances reliability.

These case studies highlight the importance of strategic planning, technical expertise, and quality products in achieving seamless 608ZZ bearing replacements. By addressing challenges proactively and leveraging lessons learned, industries can optimize equipment performance and minimize operational disruptions.

Maintenance Tips for Longevity

We delve into essential maintenance tips to ensure the longevity and optimal performance of 608ZZ bearings, focusing on regular inspection, effective lubrication techniques, and scheduled replacements.

Importance of Regular Inspection and Maintenance

Regular Inspections: Conduct routine checks to detect early signs of wear, misalignment, or contamination that could compromise bearing performance.

Preventive Maintenance: Implement scheduled maintenance programs to proactively address potential issues before they escalate, reducing downtime and repair costs.

Lubrication Techniques to Enhance Bearing Lifespan

Proper Lubrication: Use appropriate lubricants recommended by bearing manufacturers to reduce friction, dissipate heat, and prevent premature wear.

Frequency: Establish a lubrication schedule based on operating conditions and manufacturer guidelines to maintain optimal performance.

Scheduled Replacements and Preventive Measures

Replacement Intervals: Plan for periodic replacements based on bearing load capacities and operating hours to prevent unexpected failures.

Environmental Protection: Shield bearings from contaminants such as dust, moisture, and chemicals to extend their lifespan and maintain performance reliability.

Best Practices for Long-Term Maintenance

Temperature Control: Monitor operating temperatures to avoid overheating and thermal damage.

Alignment Checks: Regularly verify bearing alignment to prevent excessive loads and uneven wear.

Training and Education: Educate maintenance teams on proper handling, installation, and maintenance procedures to ensure consistent quality.

Implementing these maintenance tips ensures that 608ZZ bearings operate efficiently, extending their lifespan and optimizing performance in various industrial applications.

Conclusion

We have explored various aspects of 608ZZ bearings, focusing on their interchangeability and ensuring seamless replacements. Let's recap the key points covered and provide final tips for optimizing interchangeability.

Recap of Key Points Covered in the Guide

Throughout this guide, we emphasized the importance of:

Understanding 608ZZ Bearings: Knowing their specifications, dimensions, and load capacities is crucial for selecting suitable replacements.

Methods for Determining Compatibility: From measurement verification to cross-referencing specifications, these methods ensure the right fit.

Practical Steps for Replacement: Detailed steps from preparation to verification ensure smooth installations and minimize downtime.

Final Tips for Ensuring Seamless 608ZZ Bearing Replacements

Regular Maintenance: Implement scheduled inspections and lubrication to extend bearing lifespan and prevent failures.

Quality Assurance: Source bearings from reputable manufacturers to ensure reliability and performance consistency.

Training and Education: Continuously educate maintenance teams on best practices to optimize equipment performance.

Encouragement for Adopting Best Practices in Interchangeability

Adopting best practices in interchangeability not only enhances operational efficiency but also reduces maintenance costs and downtime. By investing in proper maintenance and selecting high-quality bearings, industries can achieve sustainable productivity and reliability.

In conclusion, prioritize proactive maintenance, utilize advanced tools and methods for compatibility verification, and leverage expert guidance to maximize the benefits of 608ZZ bearings in industrial applications. Embrace these practices to stay ahead in the dynamic field of bearing interchangeability.

FAQs: Common Questions About 608zz

We address common questions and concerns related to 608zz bearings, providing detailed answers to help you understand their applications and functionalities better.

What are 608zz bearings?

608zz bearings are deep groove ball bearings with an inner diameter of 8mm, an outer diameter of 22mm, and a width of 7mm. They are widely used in various industries for their versatility and robust performance characteristics.

Where are 608zz bearings commonly used?

608zz bearings find applications in:

Skateboards: Providing smooth rotation for wheels.

Electric Motors: Supporting shafts and reducing friction.

Conveyor Systems: Handling rotational movements efficiently.

Household Appliances: Ensuring reliable operation in fans and vacuum cleaners.

What are the key features of 608zz bearings?

Key features include:

High Precision: Accurate dimensions for consistent performance.

Durability: Able to withstand high radial and axial loads.

Noise Reduction: Smooth operation due to precision manufacturing.

Low Friction: Efficient energy transfer and reduced wear.

How can I determine if a 608zz bearing needs replacement?

You should consider replacement if:

Noise or Vibration: Increased noise or vibration during operation.

Resistance: Bearing feels rough or stiff when rotated by hand.

Visible Wear: Signs of wear such as rust, pitting, or damaged seals.

What lubrication is recommended for 608zz bearings?

Recommended lubricants include:

High-quality grease: Provides adequate lubrication and protection against contaminants.

Oil: Suitable for high-speed applications where grease may not be ideal.

How do I prolong the lifespan of 608zz bearings?

To extend lifespan:

Regular Maintenance: Perform scheduled inspections and lubrication.

Proper Installation: Ensure bearings are installed correctly with aligned shafts.

Environment Control: Protect bearings from dust, moisture, and extreme temperatures.

Where can I find replacements for 608zz bearings?

You can source replacements from:

Authorized Distributors: Ensure authenticity and quality assurance.

Online Suppliers: Access a wide range of brands and specifications.

Manufacturer Direct: Obtain OEM replacements for specific applications.

What are the benefits of using genuine 608zz bearings?

Benefits include:

Reliability: Consistent performance and longevity.

Warranty Coverage: Backed by manufacturer warranties for peace of mind.

Compatibility: Guaranteed fit and interchangeability with existing systems.

This section aims to provide comprehensive answers to frequently asked questions about 608zz bearings, empowering users with knowledge to make informed decisions regarding maintenance, replacements, and optimal use in various industrial and recreational applications.

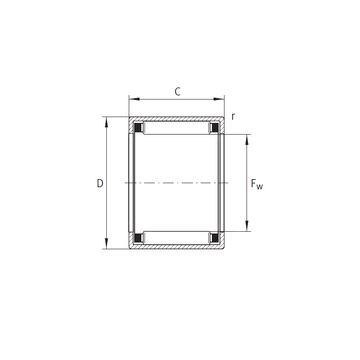

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

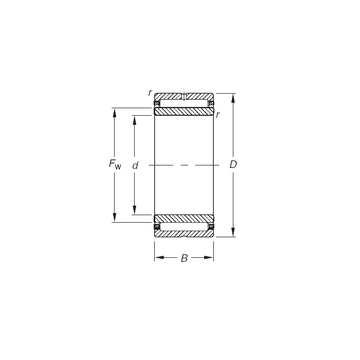

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

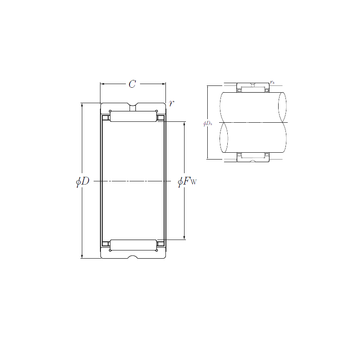

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

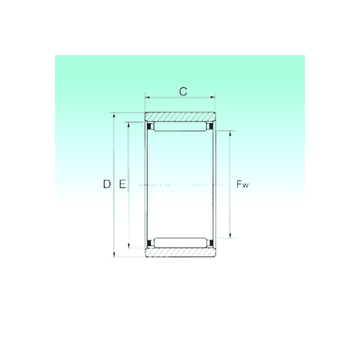

NK42/20R NTN Needle Roller Bearings