Home> Company News> Flange Bearing Manual: Understanding Applications and Selection Criteria

- AddressTianqiao, Beiyuan District, Jinan,Shandong

- Factory Addresstian qiao,jinan, shandong,China(Mainland)

- Worktime9:00-18:00(Beijing time)

- Phone(Working Time)86 0531-8299 9952

- Fax86 0531 -82990353

Introduction to Flange Bearings

Flange bearings, also known as flanged bearings, are critical components in mechanical systems, providing support and facilitating smooth rotational movement.Flange bearings are specially designed to accommodate axial loads in addition to radial loads, making them versatile for a wide range of applications in industries such as automotive, aerospace, industrial machinery, and more.

Definition and Structure of Flange Bearings

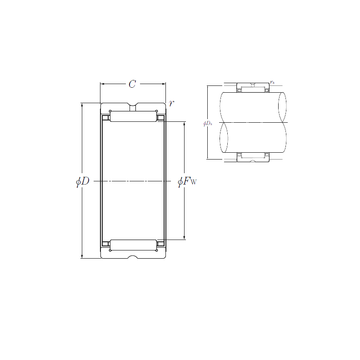

Flange bearings, characterized by their integrated flanges or rims, are mounted units containing bearings and flanges within a single assembly. These components are typically crafted from durable materials such as stainless steel, chrome steel, or various polymers, ensuring robustness and longevity under demanding operational conditions. Theflange bearing assembly consists of an inner ring, outer ring, rolling elements (balls or rollers), and a flange, which acts as a locating mechanism and aids in maintaining bearing position within the housing.

Importance of Understanding Applications and Selection Criteria

Understanding theapplications andselection criteria forflange bearings is crucial for optimizing performance and longevity in mechanical systems. Different applications require specific bearing types, sizes, and materials to withstand varying loads, speeds, temperatures, and environmental conditions. By selecting the appropriateflange bearing, engineers and designers can enhance operational efficiency, reduce maintenance costs, and extend equipment service life.

we will delve deeper into the diverse applications offlange bearings, exploring their role in different industries and providing comprehensive guidelines for selecting the rightflange bearing based on specific operational requirements.

Applications of Flange Bearings

Flange bearings, pivotal in various mechanical systems, find extensive applications across diverse industries due to their ability to support heavy loads and facilitate smooth rotational motion.Flange bearings are integral components in a wide array of applications, ranging from conveyor systems to agricultural machinery, automotive components, and industrial equipment.

Diverse Range of Applications

Flange bearings play a crucial role in ensuring efficient operation across different sectors:

|

Conveyor Systems |

In conveyor systems,flange bearings are employed to support shafts and rollers, allowing for the smooth movement of materials. These bearings withstand continuous operational cycles and varying loads, ensuring reliable performance in logistics and material handling. |

|

Agricultural Machinery

|

In agricultural machinery such as tractors and harvesters,flange bearings support shafts and rotating parts, enduring harsh environmental conditions and heavy loads. They contribute to the functionality of equipment crucial for farming operations. |

|

Automotive Components |

Within automotive applications,flange bearings are used in wheel hubs, transmissions, and engines. They enhance vehicle performance by reducing friction, supporting radial and axial loads, and ensuring precise alignment of moving parts. |

|

Industrial Equipment |

In industrial settings,flange bearings are utilized in pumps, fans, compressors, and manufacturing machinery. These bearings operate under highspeed conditions and varying temperatures, providing stability and durability in critical applications. |

Facilitating Smooth Rotational Motion and Load Support

Flange bearings are designed with integrated flanges that facilitate shaft alignment and axial positioning within housings. This design feature enhances bearing performance by reducing misalignmentinduced wear and improving load distribution across the bearing surfaces. This ensures smooth rotational motion and optimal efficiency in mechanical systems.

Types of Flange Bearings

Flange bearings are available in various types and configurations, each tailored to meet specific design and mounting requirements across different applications. Understanding the characteristics and advantages of each type is crucial for selecting the optimalflange bearing for your mechanical system.

Overview of Different Types

Round Flange Bearings

Round flange bearings feature a circular flange that extends outward from the bearing housing. This design allows for easy mounting and alignment of the bearing onto shafts or surfaces. Round flange bearings are commonly used in applications where shaft misalignment needs to be minimized, providing stable support and facilitating smooth rotational motion.

Square Flange Bearings

Square flange bearings are characterized by a squareshaped flange that provides a larger surface area for mounting onto machinery or equipment. This type offlange bearing offers enhanced stability and rigidity, making it suitable for applications that require high loadbearing capacity and resistance to deflection under heavy loads.

Oval Flange Bearings

Oval flange bearings feature an ovalshaped flange that combines the benefits of round and square designs. The elongated shape of the flange allows for flexibility in mounting positions while maintaining structural integrity. Oval flange bearings are preferred in applications where space constraints or specific mounting configurations necessitate a versatile bearing solution.

Suitable Applications Based on Design

Each type offlange bearing is designed to excel in specific applications:

Round flange bearings are ideal for conveyor systems, agricultural machinery, and automotive components where precise alignment and minimal misalignment are crucial.

Square flange bearings find applications in heavyduty industrial equipment, including pumps, compressors, and construction machinery, where robustness and loadbearing capacity are paramount.

Oval flange bearings are versatile and can be used in a variety of applications such as textile machines, packaging equipment, and medical devices, where flexible mounting options and structural integrity are required.

Conclusion

Choosing the right type offlange bearing involves considering the specific operational requirements, load conditions, and environmental factors of your application. we will delve into the selection criteria and performance considerations that will guide you in making informed decisions for your mechanical systems.

Selection Criteria for Flange Bearings

Selecting the rightflange bearings is critical to ensure optimal performance and longevity in various mechanical applications. Understanding the key factors and criteria involved in this selection process is essential for engineers and designers.

Factors to Consider

|

Load Capacity |

Load capacity is one of the primary considerations when choosing flange bearings. It refers to the maximum load that the bearing can withstand without experiencing failure or excessive wear. Different applications require different load capacities, depending on the forces exerted on the bearing during operation. |

|

Speed Ratings |

Thespeed rating of flange bearings indicates the maximum rotational speed at which the bearing can operate reliably without overheating or premature wear. Higher speeds may require bearings with special lubrication, precision manufacturing, or heat dissipation capabilities. |

|

Temperature Range |

Temperature range compatibility is crucial, especially in environments where bearings are exposed to extreme temperatures. Bearings should be selected based on their ability to withstand both high and low temperatures without compromising performance or structural integrity. |

|

Environmental Conditions |

Consider theenvironmental conditions where the bearings will be installed. Factors such as moisture, dust, chemicals, and exposure to outdoor elements can impact bearing performance. Bearings designed for specific environmental conditions ensure durability and reliability over time. |

|

Shaft Size and Tolerance |

Matching theshaft size and tolerance with the inner diameter of the bearing is essential for proper fit and functionality. Bearings that are too loose or too tight on the shaft can lead to operational issues, including increased friction, wear, and potential bearing failure. |

Importance of Choosing the Right Bearing

Theselection of flange bearings directly influences the overall performance, efficiency, and reliability of mechanical systems. Choosing the wrong type or size of bearing can result in increased maintenance costs, downtime, and reduced equipment lifespan.

Conclusion

By carefully evaluating these selection criteria—load capacity, speed, temperature range, environmental conditions, and shaft size—engineers and designers can make informed decisions when specifyingflange bearings for various industrial and mechanical applications. we will delve into the installation guidelines and maintenance practices to optimize the performance of flange bearings in diverse operating conditions.

Installation and Maintenance Guidelines

Proper installation and maintenance are crucial for ensuring the longevity and optimal performance offlange bearings. This section provides comprehensive guidelines and best practices for both installation and ongoing maintenance.

Installation Procedures

StepbyStep Instructions

Installing flange bearings correctly involves several critical steps to ensure their functionality and durability:

Preparation: Before installation, inspect the bearing and shaft for cleanliness and any signs of damage. Ensure the shaft is free of burrs or imperfections that could affect the fit.

Mounting: Carefully position the bearing on the shaft, ensuring alignment with the mounting surface. Use appropriate tools to press fit or secure the bearing as per manufacturer recommendations.

Securing: Tighten fasteners gradually and evenly to avoid misalignment or stress on the bearing. Refer to torque specifications provided by the manufacturer to achieve proper fastening.

Lubrication: Apply the recommended lubricant to the bearing as per the manufacturer's guidelines. Proper lubrication reduces friction, heat buildup, and wear, prolonging the bearing's lifespan.

Alignment: Verify the alignment of the shaft and bearing after installation. Misalignment can lead to increased vibration, noise, and premature bearing failure.

Maintenance Practices

Best Practices for Maintenance

Maintainingflange bearings ensures continued performance and reliability over time:

Regular Inspections: Periodically inspect bearings for signs of wear, corrosion, or lubrication breakdown. Replace any damaged components promptly to prevent further damage.

Lubrication Schedule: Follow a regular lubrication schedule using the specified lubricant type and quantity. Over or underlubrication can lead to bearing failure.

Environmental Considerations: Monitor the operating environment for factors such as temperature fluctuations, contaminants, and moisture levels. Take precautions to protect bearings from adverse conditions.

Condition Monitoring: Implement condition monitoring techniques such as vibration analysis or temperature monitoring to detect early signs of bearing wear or failure.

Training and Documentation: Ensure personnel responsible for maintenance are trained in proper procedures. Maintain records of installation dates, maintenance activities, and any issues encountered.

Conclusion

Adhering to theseinstallation and maintenance guidelines is essential for maximizing the performance and lifespan offlange bearings in various industrial and mechanical applications. By following best practices from installation through ongoing maintenance, engineers and maintenance personnel can ensure reliable operation and minimize downtime.

Troubleshooting Common Issues

Flange bearings are critical components in various mechanical systems, but they can encounter issues that affect their performance. This section focuses on identifying common problems and providing effective troubleshooting techniques.

Identification of Common Issues

Noise and Vibration

Flange bearings may produce unusual noise or excessive vibration due to several reasons:

Misalignment: Improper alignment between the bearing and shaft can cause vibration and noise during operation.

Lubrication Issues: Insufficient or improper lubrication can lead to increased friction and noise.

Worn Components: Wear or damage to bearing components can result in abnormal noise during rotation.

Overheating

Overheating is another common issue withflange bearings, typically caused by:

Excessive Load: Bearings operating under heavy loads without adequate cooling or lubrication may overheat.

Improper Installation: Incorrect installation techniques, such as improper fit or misalignment, can lead to heat buildup.

Troubleshooting Techniques

Diagnostic Steps

To diagnose and resolve issues withflange bearings, follow these troubleshooting steps:

Visual Inspection: Visually inspect the bearing for signs of wear, damage, or misalignment.

Check Alignment: Verify the alignment between the bearing and shaft using alignment tools.

Inspect Lubrication: Check the lubrication level and quality. Reapply lubricant if necessary.

Measure Vibration and Noise: Use vibration analysis tools to measure and analyze vibration levels. Compare against acceptable thresholds.

Temperature Monitoring: Monitor the operating temperature of the bearing using a thermometer or infrared camera. Identify any abnormal temperature rise.

Solutions and Recommendations

Addressing Issues

Once the problem is identified, implement the following solutions:

Alignment Correction: Adjust the bearing position to ensure proper alignment with the shaft.

Lubrication Improvement: Apply the correct type and amount of lubricant as recommended by the manufacturer.

Component Replacement: Replace worn or damaged bearing components promptly to prevent further issues.

Conclusion

By understanding common issues and employing effective troubleshooting techniques, engineers and maintenance personnel can ensureflange bearings operate smoothly and reliably. Regular maintenance and proactive monitoring are essential to prevent downtime and extend the lifespan of bearings in industrial and mechanical applications.

|

Brand Name |

Headquarters |

Specialization |

Key Products and Services |

Market Focus |

|

SKF (Svenska Kullagerfabriken AB) |

Sweden |

Broad range of bearing solutions |

Flange bearings, spherical bearings, seals |

Industrial, automotive |

|

Timken Company |

USA |

Highprecision bearings |

Tapered roller bearings, cylindrical bearings |

Industrial, automotive, aerospace |

|

NSK Ltd. |

Japan |

Diverse bearing solutions |

Precision bearings, automotive bearings |

Automotive, industrial |

|

Schaeffler Group |

Germany |

Highperformance bearings |

INA bearings, FAG bearings, linear guidance |

Automotive, aerospace, industrial |

|

NTN Corporation |

Japan |

Extensive product range |

Ball bearings, roller bearings, flange bearings |

Automotive, industrial, aerospace |

|

JTEKT Corporation |

Japan |

Automotive and industrial bearings |

Hub bearings, steering systems, precision bearings |

Automotive, industrial |

|

RBC Bearings Incorporated |

USA |

Customized bearing solutions |

Aerospace bearings, industrial bearings |

Aerospace, defense, industrial |

|

MinebeaMitsumi Inc. |

Japan |

Highprecision bearings |

Miniature bearings, aerospace bearings |

Aerospace, automotive, medical |

|

NachiFujikoshi Corp. |

Japan |

Precision components |

Machine tools, hydraulic equipment, bearings |

Automotive, industrial |

Case Studies and Examples

In this section, we delve into realworld applications and success stories that highlight the critical role offlange bearings across diverse industries. These case studies illustrate the significance of proper selection, application, and maintenance practices.

RealWorld Examples

Conveyor System Efficiency Enhancement

Industry: Manufacturing

Application: Conveyor Systems

Challenge: A manufacturing facility faced frequent downtime and maintenance issues due to bearing failures in their conveyor systems.

Solution: After conducting a thorough analysis, engineers selected highqualityflange bearings with enhanced load capacity and corrosion resistance. Proper alignment and regular lubrication were maintained to ensure optimal performance.

Outcome: The upgradedflange bearings significantly reduced downtime and maintenance costs. The conveyor systems operated smoothly, enhancing overall production efficiency.

Automotive Component Reliability

Industry: Automotive

Application: Suspension Systems

Challenge: An automotive manufacturer encountered noise and vibration issues in their suspension systems, affecting vehicle ride quality.

Solution: Engineers replaced existing bearings with precisionengineeredflange bearings designed to minimize friction and dampen vibrations. They implemented stringent quality control measures during installation.

Outcome: The newflange bearings improved vehicle stability and comfort, meeting stringent performance standards. Customer satisfaction increased due to enhanced ride quality.

Lessons Learned and Best Practices

Best Practices

Thorough Application Analysis: Conduct comprehensive analysis to understand load requirements, environmental conditions, and operational demands.

Proactive Maintenance: Implement regular inspection and maintenance schedules to detect potential issues early and prevent downtime.

Collaboration with Suppliers: Partner with reputable suppliers for technical support and customized solutions tailored to specific applications.

Benefits of Proper Selection

Improved Reliability: Properly selectedflange bearings enhance reliability and reduce the risk of premature failure.

Enhanced Efficiency: Optimal bearing selection contributes to improved operational efficiency and reduced operational costs.

Extended Lifespan: Wellmaintained bearings have a longer service life, minimizing replacement frequency and downtime.

Conclusion

Through these case studies and examples, it becomes evident that the selection and application offlange bearings play a crucial role in enhancing efficiency, reliability, and performance across various industries. By applying lessons learned and adopting best practices, engineers can optimize their systems and achieve superior outcomes.

Conclusion

In this comprehensiveflange bearing manual, we have explored the various facets offlange bearings, emphasizing their critical role in mechanical systems across industries. Let's recap the key points covered and highlight the importance of proper application, selection criteria, and maintenance practices.

Summary of Key Points

|

Definition and Structure |

Flange bearings are essential components designed to support axial and radial loads while facilitating smooth rotational motion. They feature a flanged housing that simplifies mounting and alignment.

|

|

Applications |

These bearings find widespread use in diverse applications such as conveyor systems, agricultural machinery, automotive components, and industrial equipment. Each application demands specific performance characteristics tailored to operational requirements. |

|

Types and Configurations |

Flange bearings come in various types including round, square, and oval configurations, each suited to different mounting and loadbearing capacities. |

|

Selection Criteria |

When choosingflange bearings, factors like load capacity, speed, temperature resistance, environmental conditions, and shaft size must be carefully evaluated to ensure optimal performance and longevity. |

Installation and Maintenance: Proper installation techniques, adherence to maintenance schedules, and proactive troubleshooting are crucial for maximizing the lifespan and efficiency offlange bearings.

Importance of Understanding Applications and Selection Criteria

Understanding the precise application requirements and selecting the rightflange bearings based on these criteria is paramount. It not only enhances operational efficiency but also prevents premature failures, reducing downtime and maintenance costs.

Final Thoughts

The reliability and longevity offlange bearings hinge on meticulous attention to detail throughout their lifecycle. From initial selection to installation, regular maintenance, and troubleshooting, every step influences their performance in mechanical systems.

By adhering to best practices and leveraging technological advancements, engineers and maintenance professionals can ensure thatflange bearings continue to operate at peak efficiency, contributing to overall system reliability and productivity.

In conclusion, the knowledge gained from this manual empowers professionals to make informed decisions regardingflange bearings, thereby optimizing their applications and achieving superior performance in diverse industrial settings.

FAQs: Common Questions About Flange Bearings

What are flange bearings?

Flange bearings, also known as flanged bearings, are mechanical components designed to support and facilitate rotational or linear movement within a machine or mechanical system. They are distinguished by their flanged housing, which provides support and alignment for the bearing and shaft assembly.Flange bearings play a crucial role in various applications where precise positioning and smooth operation are essential.

What are the key components of a flange bearing?

Aflange bearing typically consists of several key components:

Bearing Housing: The outer casing that supports the bearing insert.

Bearing Insert: The inner component that houses the rolling elements, such as balls or rollers.

Flange: The integral part of the housing that extends outwards to provide mounting and positioning support.

What are the types of flange bearings available?

Flange bearings come in various types to suit different applications and mounting requirements:

Round Flange Bearings: Circular flanges that provide radial support.

Square Flange Bearings: Squareshaped flanges for secure mounting.

Oval Flange Bearings: Elongated flanges that offer flexibility in positioning.

How do I select the right flange bearing for my application?

Selecting the appropriateflange bearing involves considering several factors:

Load Capacity: Ensuring the bearing can handle the anticipated loads.

Speed: Determining the rotational speed requirements.

Temperature and Environment: Considering operating conditions such as temperature and exposure to contaminants.

Shaft Size: Matching the bearing's bore size to the shaft diameter for proper fit.

What are the common applications of flange bearings?

Flange bearings find applications across diverse industries, including:

Conveyor Systems: Supporting rollers and shafts in material handling equipment.

Automotive Components: Facilitating movement in steering systems and engines.

Agricultural Machinery: Enabling smooth operation of farm equipment.

Industrial Equipment: Providing support in pumps, compressors, and gearboxes.

How should I install and maintain flange bearings?

Proper installation and maintenance are crucial forflange bearings to operate efficiently:

Installation: Ensure correct alignment and secure mounting to prevent misalignment and premature wear.

Maintenance: Regular lubrication and inspection to detect signs of wear, noise, or overheating.

Troubleshooting: Diagnosing issues promptly to prevent further damage and ensure prolonged service life.

What are the benefits of using flange bearings?

Flange bearings offer several advantages, including:

Space Efficiency: Compact design suitable for applications with limited space.

Alignment: Flanges aid in precise alignment of the shaft and bearing assembly.

Load Capacity: Ability to support heavy loads without compromising performance.

Versatility: Available in various configurations to meet specific application requirements.

This section covers the essential FAQs aboutflange bearings, providing insights into their functionality, types, selection criteria, applications, installation, maintenance, and benefits.

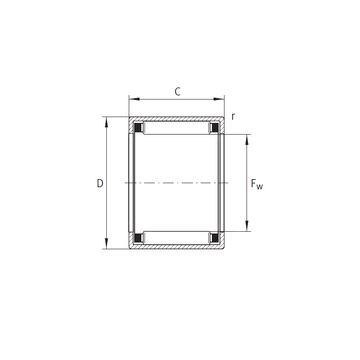

SCE5612 INA Needle Roller Bearings

SCE5612 INA Needle Roller Bearings NKJ20/16 Timken Needle Roller Bearings

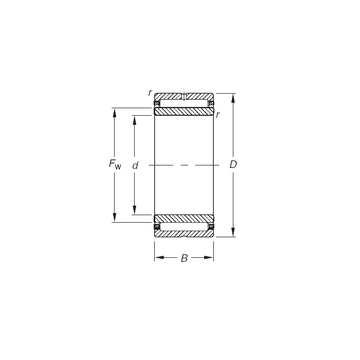

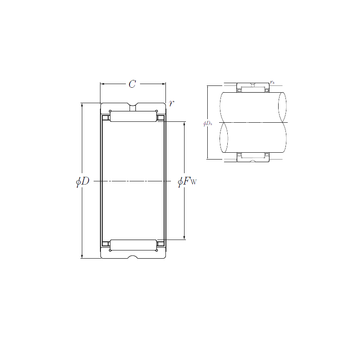

NKJ20/16 Timken Needle Roller Bearings RNA4976 NTN Needle Roller Bearings

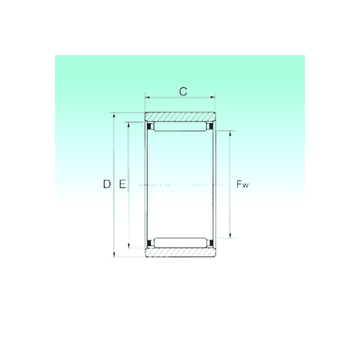

RNA4976 NTN Needle Roller Bearings RNAO 35x47x16 NBS Needle Roller Bearings

RNAO 35x47x16 NBS Needle Roller Bearings NK42/20R NTN Needle Roller Bearings

NK42/20R NTN Needle Roller Bearings